Revolutionizing Quality Control: The Integration of Advanced Metal Detector and Checkweigher in Production Lines

Introduction

## Chapter 1: Understanding Metal Detectors

## Chapter 2: Checkweighers in Precision Measurement

## Chapter 3: The Synergy of Integration

## Chapter 4: Real-world Applications

## Chapter 5: Future Trends and Innovations

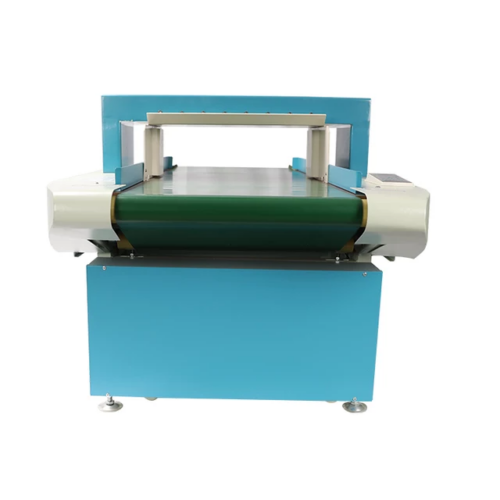

This machine utilizes high-speed digital signal processing components and intelligent algorithms. It features an LCD display with a menu available in both Chinese and English, as well as LED signal indicators. It has self-learning capabilities, able to automatically find suitable phases and set sensitivity. It possesses product sequence memory storage, with a capacity of up to 52 items. It can detect foreign metallic objects such as iron, stainless steel, copper, aluminum, lead, etc.

Product specifications

| Item Name | Fully digital intelligent metal foreign object detector |

| Model | VKD-II |

| specifications | 230S-4H |

| Material | Whole machine: Manufactured entirely in stainless steel 304 |

| Detection sensitivity | Fe≥φ0.5mm Nofe≥1.0mm Sus304≥φ1.2mm |

| Effective detection size | 230mmW*100mmH |

| Weighing platform dimensions | 350mm L,230mm W |

| Maximum sorting accuracy | ±0.2g |

| Maximum load-bearing capacity | 2000g |

| Conveyor belt height | 750mm(adjustable up to 100mm) (customizable based on site conditions) |

| Conveyor belt speed | ≤70m/min |

| Power supply | AC220V |

| Rejecting mode | Double-swing arm rejection |

| Conveying direction | From left to right or from right to left |

| Alarm mode | Stop alarm or automatic rejection |

Note:

- The sensitivity mentioned above is tested with the test block placed on the surface of the conveyor belt. Actual sensitivity may vary depending on the tested product.

- Made entirely of stainless steel with a high level of dust and water resistance. Special specifications can be customized according to customer requirements at an additional cost.

- The sensitivity of the product may vary slightly depending on the size and quantity of the packaged items being inspected.

- For situations where the spacing between products is not fixed or when products are excessively long, it is recommended to adopt a stop-alarm rejection method.